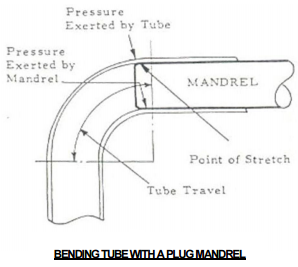

While not all bends require a mandrel, using a mandrel can offer a number of advantages. The purpose of a plug mandrel, for instance, is to prevent the tube from flattening as well as allowing the bend to be completed without wrinkles or kinks. Sometimes, however, even when using a mandrel tube wrinkling can occur.

What is Mandrel Tube Bending?

When using a mandrel tube bender, the mandrel is held in a fixed position while the tube is pulled over it. The tube stretching process is localized on the outer radius of the bend, and the material is work-hardened to retain its shape and not flatten. The material stretching is done on the forward tip of the mandrel. This force, acting on the mandrel tip, supports the inner radius of the bend, holding it firmly into the bend die groove.

Sometimes, however, problems can occur when bending. One of the most common problems we run across is tube wrinkling. There are a number of reasons that a tube may be wrinkling when using a mandrel tubing bender.

Top 8 Reasons for Tube Wrinkling

- Tube slipping in clamp die

- Mandrel is not far enough forward

- Wiper die not seated properly in bend die

- Wiper die worn or of improper fit

- Too much clearance between mandrel and tube

- Not enough pressure on the pressure die

- Improper or excessive amount of lubrication

- If mandrel and wiper die are in proper locations, check inboard pressure on the pressure die. You may need to apply more pressure on the pressure die to hold the tube into the die. Adjust in slowly until you have no wrinkles. Lastly, check mandrel fit.

Tube Bending Automation Cell

When using a traditional mandrel tube bending machine, troubleshooting can be a time-consuming process. Placement and positioning must be manually checked, and when complex or multiple bends are being performed on one machine, this can be a substantial task.

A tube bending automation cell can, among many other benefits, help to prevent some of the most common causes of tube wrinkling and also speed up the troubleshooting process.

A tube bending automation cell offers an easy setup and easy-to-use 3D software with a touchscreen. These make programing and using the tube bending automation cell for mandrel tube bending simpler and faster than manual bending. Because setup can be checked and potential problems explored within the software, often problems can be identified before a piece is bent.

Automation cells also offer robotic, automatic loading and unloading over a mandrel. This helps prevent some of the human errors that can lead to tube wrinkling.

You can see our tube bending automation cell in action below.

Learn More

Click here or follow the link below to download a free introduction to tube bending to learn more, troubleshoot bending problems, or contact us at any time with any questions or comments you may have.