Tube End Forming Solutions

Experience VLB Group’s top-notch tube end formers that offer high precision.These have unmatched engineering skills combined with remarkable artistry for unprecedented outcomes.The design of precision tube end formers ensures top quality is upheld,thus resulting in perfect results as per one’s needs. Discover what sets VLB Group apart by checking out the full list of products in store, the latest features incorporated,the honest client feedback.experience high-quality finishes every time due to our advanced machines. Enjoy perfect results each moment you use them. Leave for VLB group where all pipe ends attest to unmatched excellence so that you run a precision journey. Explore and invest in quality products from VLB Group.

Enquire Now Download Spec Sheet

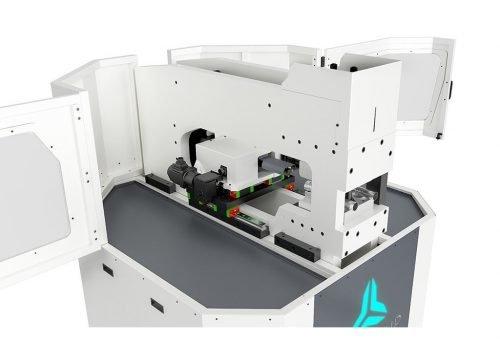

VLB’s EF series end prep machines are extremely fast, precise and versatile; they are designed for many functions. This makes it easy to have various pipes that differ in complexity, deformation degrees, and repeatability done with these end preparing machines. There is a servo motor-controlled sequence of tools where linear positioning together with numerical command that is simple to program ensures speed of motion and high precision. With possibility of a maximum of 6 forming stations which include also rotary stations; this is just how powerful our tube-end forming machines can be when fully automated.

Maintenance is simplified Besides the technical aspects

EF tube end forming machines have been developed so as to ease the use and maintenance operations.The compact design means that all the components are easily accessible to any of the user. When you open these panels for safety, the entire front part of your machine can be reached and intervened with as it acts like doors.

Friction is not a problem because nothing moves around (like wheels do when they rotate). High quality materials known in manufacturing these days ensure that the power needed by each machine part respectively has been economized on as much as possible; however this reduces speed considerably because they can’t be made more cheaply if their production costs are cut down too much but still keeping good quality standards. This is why such kind of machines are usually referred to as “expensive low-speed ones” and even though they are pretty consistent in terms of what they make, their capacity is limited due to the fact that there is only one of them. The cost of maintenance can be significantly lowered in such situation.

HMI INTERFACE

The touchscreen easily and conveniently enables users to make advances on the powerful control of the EF pipe end machining through programming. This way, the same consistency as the entire software developed by our IT department is met when it comes to ease of programming, intuitiveness, among others. As far as instructions communication is concerned, it seems pleasant and logical from an operator's point of view.

For instance, considering that the software enables changing and storing of sequences and parameters for every operation, it further grants effortless integration with tube handling systems like loading and unloading system and other production cells such as bending machines.

Videos

FAQs Related to Tube End Formers

Well, it's a pretty nifty machine that's specifically designed for shaping and forming the ends of tubes. You see, it's used to create all sorts of end configurations, like flaring, expanding, reducing, and beading.

Tube End Formers are actually super important because they shape the ends of tubes to meet specific design and functional requirements. This fancy process helps make the tubes more versatile and functional for all sorts of applications. Pretty cool, right?

Our Tube End Formers are versatile and can achieve a variety of end configurations, including flaring, beading, reducing, and expanding. These configurations cater to different industry needs and applications.

Absolutely! Tube Form Solutions' Tube End Formers are designed to handle a wide range of tube materials, such as steel, aluminum, and stainless steel. Not only that, but they are also incredibly adaptable to different tube sizes. This means you have the flexibility to meet various manufacturing needs. So, whether you're working with steel, aluminum, or stainless steel tubes of different sizes, our Tube End Formers have got you covered!

Tube End Formers are commonly found in industries like automotive, aerospace, HVAC, and plumbing. They are highly versatile and can be used in applications where precise end configurations are crucial.

Please refer to the specifications on our product page or contact our team for detailed information on the maximum tube size our Tube End Formers can accommodate. Our machines are designed to handle a wide range of tube diameters.

Absolutely! Tube Form Solutions has designed their Tube End Formers to be highly adaptable and seamlessly integrated into your current manufacturing processes. They're specifically crafted to enhance your production line's capabilities without causing any major disruptions. So, you can easily incorporate them into your existing setup and enjoy the benefits they bring.

The key features include precision end forming capabilities, versatility in achieving different configurations, user-friendly controls, and robust construction for durability. These features collectively contribute to efficient and reliable end forming operations.

Yes, we offer comprehensive training for operators to ensure they can effectively use Tube End Formers. Our training programs cover machine operation, safety protocols, and maintenance procedures to ensure optimal performance.

Lease A New Tube End Forming Machine

Through our financing partners, you’ll find financial programs, leasing, and loan services at very competitive rates. No Financials or Tax Returns are required* and credit decisions are usually made within 24 hours.