When setting bend tooling, the goal is never to produce unnecessary bulges or distortions in the tubing you are bending.

However, even a set of tooling that has been properly placed and a bend that has been properly executed can leave some surface abrasions, scratches, or other marring of the tubing.

Typically this isn't an issue for the final product, but there are applications where the bent tubing needs to be clean. When this is the case, you typically have two options.

First, you can polish the finished piece to remove the tooling marks. The other option is to opt for no-mar tube bending tooling.

What is no-mar tube bending tooling?

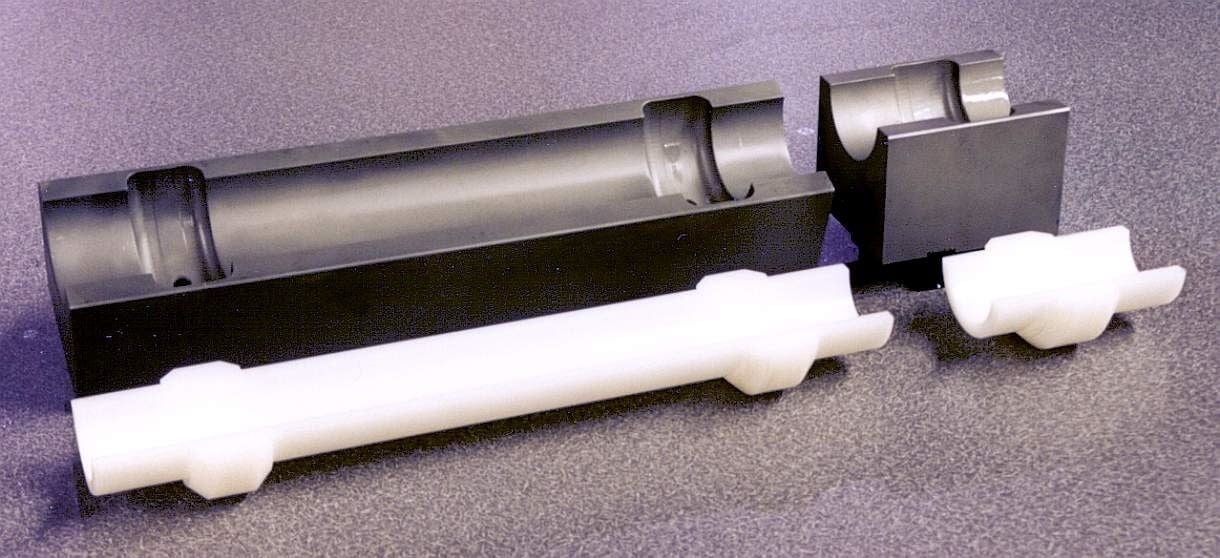

Typically, bend tooling is made from metal because metal is durable, long-lasting, and capable of bending tubes and pipes easily.

However, many advances have been made in plastic tooling in recent years, and the result is much more durable than you might think.

Metal tooling still has advantages over plastic tooling, but for applications where the aesthetics of the bend are important, no-mar tooling can be an ideal solution. Where traditional metal tooling will leave tooling marks, plastic no-mar tooling will not.

With no-mar tooling, the bend results in a clean, up-marred surface that doesn't require additional buffing and polishing.

Why use no-mar tooling?

For many applications, no-mar tooling is an unnecessary expense. However, there are applications where it can be a cost-effective solution. Typically no-mar tooling is used on steel, stainless steel, aluminum, copper, or painted materials where the product appearance needs to remain scratch free.

One example of an application where no-mar tooling is ideal is food service. Tube and pipe that is destined for food service applications often need to be smooth.

Any scratches, dents, or scrapes left on the tubing

In settings where sanitation is critical, any step you can take to reduce the risk of bacterial growth is worth the expense.

Other common applications include bending painted or polished parts. For some applications, the paint/polish must be applied before the bend. No-mar tooling allows the surface treatment to remain intact.

Learn More

Click here or follow the link below to download a free introduction to tube bending to learn more, or contact us at any time with any questions or comments you may have.