Employing a mandrel when pipe bending is a common solution for several tube bending issues and problems. So, what do you need to know about mandrels?

When using a mandrel for pipe bending, the tube is pulled over the mandrel, which is held in a fixed position. A plug mandrel is recommended for tubing 3/8' in diameter and smaller.

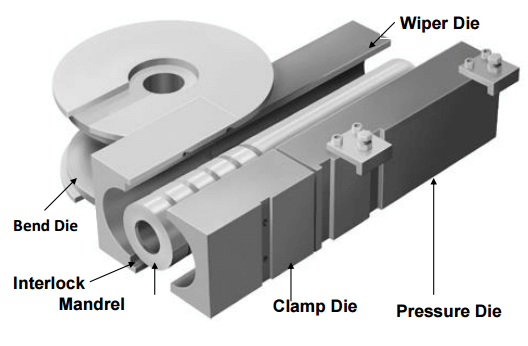

However, when the radius of the bend is smaller and/, or the wall is thinner, it becomes necessary to use a ball mandrel and wiper die to maintain the proper shape.

In addition to using a mandrel setup, a wiper die is necessary with tight bends or thin wall tubing. This is because bending issues become enlarged with these types of bends. With tight bends or thin wall tubing, retaining the material during compression is difficult.

The pressure during this type of bend is so intense the material is squeezed back past the tangent and buckles without the aid of a wiper die.

Regardless of which type of mandrel setup is used, employing a mandrel is done to prevent some of the most common tube bending problems or issues.

Perhaps most importantly, a mandrel will help prevent spring back. Spring back is the tendency of a metal to return to its original shape. Mandrels also help prevent flattening, wrinkles, and kinks.

Learn More