Some of our most frequently asked questions revolve around how to bend tubes accurately. Because each situation and application is different, often the best place to begin bending tubes accurately is with a solid understanding of the fundamentals of bending, how you bend tubes, and the tooling that is necessary for bending.

What Happens When a Tube is Bent?

What Happens When a Tube is Bent?

When a tube is bent, two things happen to the metal. The first is that the outside wall is reduced in thickness. The stretching of the material causes this reduction. The second thing that happens is that the inside wall becomes thicker due to the compressing of the material.

The material that forms outside the bend has further to travel, which causes the stretching. The inside of the bend has less distance to travel and is compressed.

Understanding what is happening to the material as it is bent is critical for accurate bending. Setup and troubleshooting require you to grasp this basic concept well.

What Do You Need to Bend a Tube

Now that we understand the basics of bending, it is important to understand how we bend. To bend the tube accurately, you will need a few basic pieces of tooling.

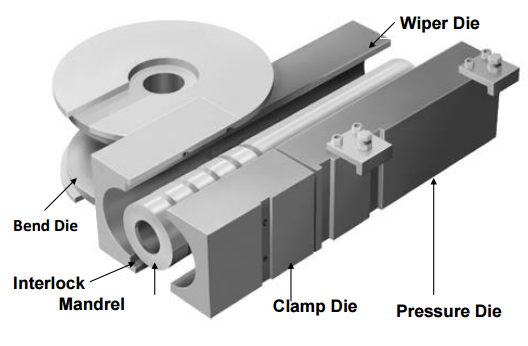

A bend die, clamp die, and pressure dies are the minimum essentials for bending tubes. However, there are often other pieces of tooling that are also used. However, the bend, clamp, and pressure die are the necessary pieces of the tooling.

The bend die helps to prevent the tube from flattening and forms a given radius of the bend.

The clamp die holds the tube in position while bending.

The pressure die forces the tube into the bend die.

Wiper dies are also often used. Wiper dies support the inside of the tube to help prevent the formation of wrinkles during bending. Mandrels also prevent common bending problems like tube collapse, and kinked, or buckled bends.

Understanding the tooling you work with is crucial to accurate tube bending. You can learn more about the most common types of tooling here.

How to Bend Tube Accurately

Once you have grasped the fundamentals of how a tube is bent and are familiar with the tooling necessary to bend a tube accurately, the most important thing you can do to bend accurately is set up your tooling correctly.

So often, the reason for common bending problems is improperly set tooling. Checking the positioning of the tooling is almost always the first step in troubleshooting any bending problem.

Precise tooling setting is key to accurately bending the tube.

Learn More

Click here or follow the link below to download a free introduction to tube bending to learn more, troubleshoot bending problems, or contact us anytime with any questions or comments you may have.