Automated Bending Cells

The repeatability of an automated bending and forming cell opens new doors that companies thinking of exploring this space for the first time should consider. It addresses the labor shortage, increases productivity, and allows manufacturers to more aggressively and accurately bid work.

Roughly 87% of bending operations with 2 benders or more have not turned to automated bending. Of that 87%, we estimate that it would be a very viable option for at least 50%.

Many operations make a profit with hand loaded bending and forming operations and will continue to do so . Many parts are either too low volume or too large and cumbersome to work within an automated cell.

If you're not regularly repeating parts and seeking a high throughput of like parts, it may not make sense to invest in the infrastructure that goes with an automated bending solution.

The labor shortage has been a significant factor driving companies to automate as the baby boom generation is still retiring (and taking its knowledge and skills with them) and we are not back filling our workforce with young, trained, and skilled manufacturing people. Manufacturing is a rare field in this climate where there is a huge demand for labor and not enough skilled people to fill it.

The main goal of automating these processes is eliminating variation reducing costs and to produce a higher quality product (better, faster, cheaper).

Adding automation to a bending operation doesn't just help increase your throughput it also helps identify variation and bottlenecks in your upstream process which, when identified, can be corrected, thus additional productivity.

When considering whether to automate you really need to look at your operation and identify what a human does well and what a robot does well. Manual operators are very good at making judgment calls, a bender operator, for instance, can see a wiper die is worn and needs replacing before any scrap parts are run. On the other hand, a robot cannot make a judgment call but is very good at repeatability, so there still has to be human oversight of a successful automation cell, taking the judgment out of the robots equation, or the success will be limited.

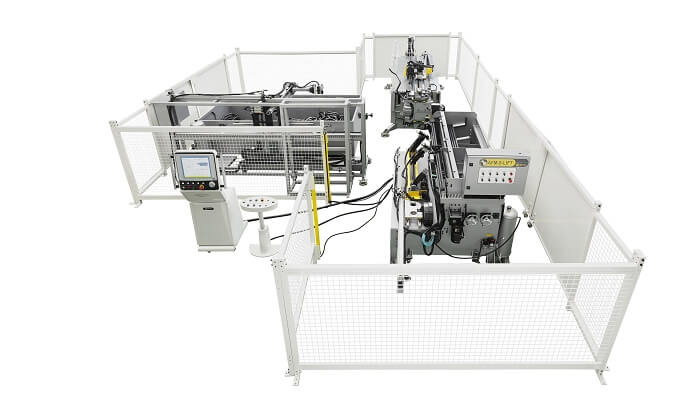

Manufacturers tend to be intimidated by automated bending systems, will I have to rearrange my facility? Will we have to add another building? In some cases, the answer is yes, but manufacturers now offer pre-engineered robotic bending systems that include everything to integrate to your current equipment. These systems can be dropped into current workflows and put into operation.