When you think of tubes and pipes, what comes to mind? For many, plumbing is the first thought, but there are plenty of other everyday objects that use tubes and pipes.

From pipes for fuel and liquids in our cars to objects such as musical instruments (think the U-bend of a trombone), any item that requires piping also requires those tubes to be bent at a specific angle or curve. After all, it's rare to see plumbing applications with nothing but straight pipes.

Tubes and pipes formed for specific purposes and machinery are often completed on tube bending equipment, which uses a variety of tube bending formulas and techniques to achieve the proper angle and shape for the pipe. Pipe and tube bending equipment can include such devices as dies, mandrels, and various types of presses that form the tube's shape.

For the most part, this equipment is operated in factories, workshops, and other locations with professional manufacturers. However, some plumbers may also rely on tube bending equipment for custom piping jobs.

Why Is Precision Bending Important?

Why is the precise angle of every bend so important? In many applications, the angles of the bends are integral to their function.

In an automobile engine, for instance, a tube or hose must be precisely bent in order to fit in with the other components around it. If the calculations are incorrect parts of the engine, or even the whole system, won't be able to function properly. For instance, if a pipe is improperly bent fluids cannot be transferred from one part to another, and the whole engine may be unable to function.

Another example of this is the plumbing pipes in your home. If the pipes in your home are not shaped in a way that will properly remove waste or send water to your faucet, then clogs, leaks, and breakdowns can occur.

How Are Pipes Bent?

In general, however, when a machine is being used to bend a pipe the pipe is loaded onto the machine, the bend specifications are programmed in, the tooling is set, and the machine bends the pipe.

The machines that are used to bend pipes can be operated by humans or through automated processes; they may be powered manually or through pneumatic, electric, or hydraulic power. Computer numerical control or CNC machines can be programmed for larger manufacturing and pipe bending jobs because they can store settings.

CNC pipe bending machines are ideal for high-volume applications that require complex bends and high precision.

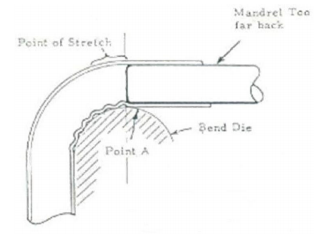

There are a number of common pieces of bending equipment. Tube bending dies are some of the most common pieces of tube bending equipment. The die is a device in a particular shape made for the pipe to wrap around and create the correct curve or angle, sort of like a manufacturing mold.

Another common piece of equipment is a mandrel. Mandrels are used to help maintain the shape of the pipe as it sets into the arc of the bend. When using a mandrel, the pipe is pulled over the mandrel, which provides support for the pipe and holds it firmly against the bend die.

Learn More

Click here or follow the link below to download a free introduction to tube bending to learn more, or contact us at any time with any questions or comments you may have.