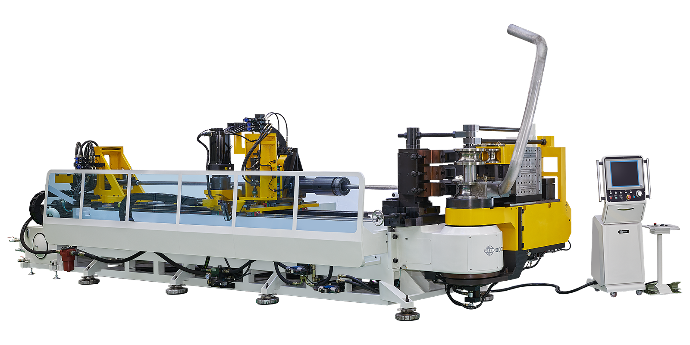

5B Series Heavy Duty CNC Benders

Models extend up to 127mm capacity; the 5b series tube bender brings the optimal tube bending power and accuracy solutions for automotive, trucking, buses, boiler, ship building and other heavy industries.

Enquire Now Download Spec Sheet

Introduction to 5B Series Heavy Duty CNC Benders

Lease A New Machine 5B Series Heavy Duty CNC Benders

Through our financing partners, you’ll find financial programs, leasing, and loan services at very competitive rates. No Financials or Tax Returns are required* and credit decisions are usually made within 24 hours.N