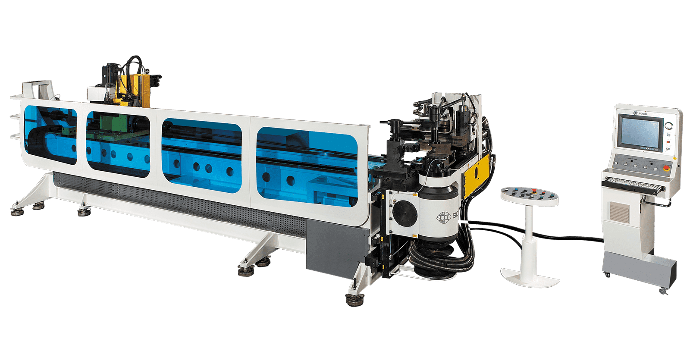

PT Series Wall Thinning Benders

Engineered for manifolds, converter inlets, and other tight-CLR exhaust parts, the SOCO PT Series controls wall thinning on 1D bends for high-pressure assemblies. Choose all-electric or proportional-servo bending with up to 12 CNC axes and 3–22 tons of programmable boost. Pair PT with i2 software, stack tooling, and automation for repeatable accuracy and faster changeovers.

Request a Quote Download Spec Sheet

Overview of PT Series Thin-Wall Benders

Lease A New Machine PT Series Wall Thinning Benders

Through our financing partners, you’ll find financial programs, leasing, and loan services at very competitive rates. No Financials or Tax Returns are required* and credit decisions are usually made within 24 hours.