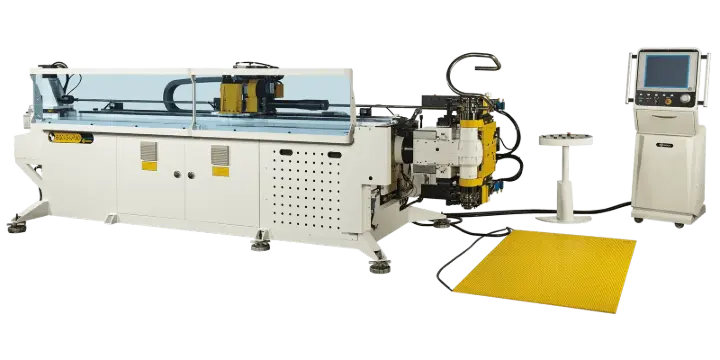

Ultimate Guide to CNC Tube Benders: Types, Applications & How to Choose the Right Machine

CNC tube benders are essential tools in modern manufacturing, enabling precise and efficient bending of tubes for various applications. This comprehensive guide will explore the different types of CNC tube benders, their features, and how to select the right machine for your specific needs. Understanding the nuances of CNC tube bending can significantly enhance production efficiency and product quality, addressing common challenges faced by manufacturers. We will delve into the main types of CNC tube benders, their applications across industries, and key selection criteria to consider when investing in this technology. Additionally, we will highlight the importance of precision technologies and maintenance practices to ensure optimal performance.

What Are the Main Types of CNC Tube Benders and Their Features?

CNC tube benders come in various types, each designed to meet specific bending requirements. Understanding these types is crucial for selecting the right machine for your operations.

How Do All-Electric CNC Tube Benders Deliver Precision and Energy Efficiency?

All-electric CNC tube benders utilize electric motors to drive the bending process, offering exceptional precision and energy efficiency. These machines are known for their ability to produce consistent bends with minimal variation, making them ideal for applications requiring high accuracy. The energy efficiency of all-electric systems also translates to lower operational costs, as they consume less power compared to hydraulic systems. This makes them particularly suitable for industries focused on sustainability and cost-effectiveness.

The drive for enhanced precision and efficiency in modern manufacturing is further supported by continuous advancements in CNC bending technology.

High Precision Four-Roll CNC Bending for Aerospace & Automotive In recent years, advancements in industries such as aerospace, military weaponry, automobiles, locomotives, and shipbuilding have led to a surge in the demand for bent and rolled components, along with increasingly stringent requirements for rolling precision. To address these challenges, servo electric cylinders have been introduced as a replacement for traditional hydraulic cylinders, resulting in higher control precision and faster response times, ultimately providing a comprehensive design solution for four-roll CNC bending machines. Design and development of high precision four roll CNC roll bending machine and automatic control model, 2023

What Are the Advantages of Hydraulic and Hybrid CNC Tube Benders?

Hydraulic and hybrid CNC tube benders offer distinct advantages that cater to different manufacturing needs. Hydraulic systems are renowned for their power and versatility, capable of handling thicker materials and complex bends. They provide robust performance in high-demand environments, making them a popular choice for heavy-duty applications. On the other hand, hybrid systems combine the benefits of both electric and hydraulic technologies, offering flexibility and efficiency. These machines can adapt to various bending tasks, making them suitable for diverse manufacturing processes.

Which Industries Benefit Most from CNC Tube Bending Applications?

CNC tube bending technology is utilized across multiple industries, each benefiting from its unique capabilities.

How Is CNC Tube Bending Used in Automotive and Aerospace Manufacturing?

In the automotive and aerospace sectors, CNC tube bending is critical for producing components such as exhaust systems, frames, and structural supports. The precision offered by CNC technology ensures that parts fit perfectly, enhancing overall vehicle performance and safety. Additionally, the ability to create complex shapes allows manufacturers to optimize material usage, reducing waste and costs.

Further illustrating the innovative capabilities of CNC technology, new methods are continually being developed to achieve even greater flexibility and complexity in tube bending.

CNC MOS Bending for Flexible 3D Tube Manufacturing 1. This article presents an innovative computer numerical control (CNC) tube forming method, called MOS bending, which manufactures flexibly and 3-dimensionally bent tubes and was put into practical use in industry. The machine for MOS bending is mainly composed of a bending die and a guide cylinder. Numerically controlled positioning of the bending die in vertical and horizontal directions realizes flexible bending in arbitrary bending radius and arbitrary direction. The variety of the bent shapes includes conventional 2-dimensional arcs, convoluted patterns in a plane, extremely large bending radii, 3-dimensional solenoids and other 3-dimensional complex shapes. The flexibly bent tubes are suitable for ornamental usages as interior and exterior decorations as well as automotive components. MOS bending revolutionarily changes the image of tube bending. The above and other benefits of MOS bending are reviewed here, together with its mechanism and some examples of products. CNC tube forming method for manufacturing flexibly and 3-dimensionally bent tubes, 2015

What Are the Applications of CNC Tube Benders in HVAC, Furniture, and Medical Sectors?

CNC tube benders play a vital role in HVAC systems, furniture design, and medical device manufacturing. In HVAC, they are used to create ductwork and piping that require precise bends for efficient airflow. In furniture design, CNC tube bending allows for innovative shapes and structures, enhancing aesthetic appeal. The medical sector benefits from CNC tube benders in the production of equipment such as surgical instruments and hospital furniture, where precision and reliability are paramount.

How to Choose the Right CNC Tube Bender for Your Business Needs?

Selecting the appropriate CNC tube bender involves considering several key factors to ensure it meets your operational requirements.

What Selection Criteria Should You Consider: Material, Capacity, and Accuracy?

When choosing a CNC tube bender, it is essential to evaluate the materials you will be working with, the machine's capacity, and the required accuracy. Different machines are designed to handle various materials, such as steel, aluminum, or copper, each with unique bending characteristics. Additionally, understanding the machine's capacity in terms of tube diameter and wall thickness is crucial for ensuring it can accommodate your production needs. Finally, accuracy is vital for maintaining quality standards, so selecting a machine with high precision capabilities is essential.

How Do Automation Features and Software Influence CNC Tube Bender Selection?

Automation features and software capabilities significantly impact the selection of CNC tube benders. Advanced machines come equipped with user-friendly interfaces and software that streamline the programming process, allowing for quick setup and adjustments. Features such as anti-collision systems and real-time monitoring enhance operational efficiency and reduce the risk of errors. Investing in a machine with robust automation capabilities can lead to increased productivity and reduced downtime.

What Are the Key Precision Technologies and Software Features in CNC Tube Bending?

Precision technologies and software play a crucial role in enhancing the performance of CNC tube benders.

How Does Advanced 3D Software and Anti-Collision Simulation Improve Bending Accuracy?

Advanced 3D software allows operators to visualize the bending process before execution, ensuring that all parameters are set correctly. This technology helps identify potential issues, such as collisions, before they occur, significantly improving accuracy. Anti-collision simulation features further enhance this capability by providing real-time feedback during the bending process, helping to prevent collisions and ensuring that the machine operates smoothly and efficiently.

What Role Does Industry 4.0 Integration Play in Modern CNC Tube Benders?

The integration of Industry 4.0 technologies into CNC tube benders is transforming manufacturing processes. By incorporating IoT devices and data analytics, manufacturers can monitor machine performance in real-time, leading to proactive maintenance and reduced downtime. This connectivity allows for smarter production strategies, optimizing resource allocation and enhancing overall efficiency.

What Are Essential Tube Bending Tooling and Maintenance Practices?

Proper tooling and maintenance practices are vital for ensuring the longevity and performance of CNC tube benders.

Why Are Mandrels, Wiper Dies, and Clamp Dies Critical for Quality Bends?

Mandrels, wiper dies, and clamp dies are essential components in the tube bending process. Mandrels support the tube during bending, preventing deformation and ensuring a smooth curve. Wiper dies help maintain the tube's shape and finish, while clamp dies secure the tube in place, preventing slippage. Utilizing high-quality tooling is crucial for achieving consistent and high-quality bends.

How Should You Maintain CNC Tube Benders for Long-Term Performance?

Regular maintenance is key to the long-term performance of CNC tube benders. Operators should establish a routine maintenance schedule that includes cleaning, lubrication, and inspection of critical components. Monitoring wear and tear on tooling and machine parts can prevent unexpected breakdowns and extend the machine's lifespan. Implementing a proactive maintenance strategy ensures that CNC tube benders operate at peak efficiency, minimizing downtime and maximizing productivity.

Type of CNC Tube Bender | Key Features | Ideal Applications |

All-Electric | High precision, energy-efficient | Automotive, aerospace, medical |

Hydraulic | Powerful, versatile | Heavy-duty applications |

Hybrid | Flexible, efficient | Diverse manufacturing processes |

CNC tube benders are indispensable tools in modern manufacturing, offering precision and efficiency across various industries. By understanding the different types of machines, their applications, and key selection criteria, businesses can optimize their production processes and enhance product quality. Investing in the right CNC tube bender, along with proper tooling and maintenance practices, will ensure long-term success in tube bending operations.