Use of bend dies

Rotary draw bending is the most popular form of tube and pipe bending. Used in industries as diverse as aerospace and automotive, rotary draw bending can create precision bends in a repeatable process with the use of precision tooling and dies sets.

Choosing a Bend Die

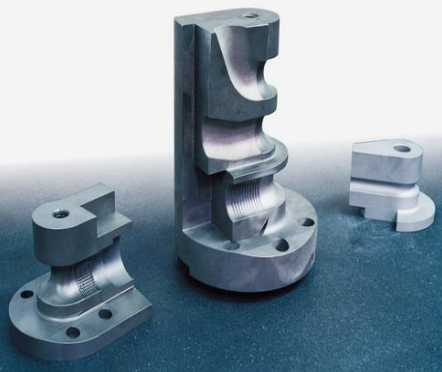

Most often the type of bend will dictate the type of die that is appropriate. For instance, when the height is larger than the width you will most often use a pedestal and flange mount bend die. This type of rotary draw bending die incorporates a platform for added stability and may, or may not, have a tool post.

The first step in choosing a bend die will be determining the material you will be bending and the type of bend you will be performing. Together, these two pieces of information will inform your die choice.

Learn More

The Introduction to Rotary Draw Bending Tooling is a good place to start. Stuffed full of easy to understand diagrams and images that are accompanied by clear information, walking readers through the basics of bending tooling. Inside the guide you fill find:

- Engineering Guidelines

- Tight Radius Bending

- Completing the Application Review

- Special Considerations & Applications

- Summary and Benefits

Click here or click the button at the bottom of this post to download the Introduction to Rotary Bending Tooling.