What is the difference between a single hit, or strike, end forming machine and a multi strike machine? Both machines use tooling to either expand or decrease the diameter of a tube or pipe or change its shape. In comparing both types of machines you can often find the same or similar features between models. So what is the difference?

Single Hit Ram form expansion

Single Hit Ram form expansion

The greatest difference between a single and multi-strike ram forming machine is, unsurprisingly, in the process they use to form or shape the ends of a tube or pipe.

A ram form expansion stretches the material as a diameter and not a short valued area. This allows the material to flow and not stretch throughout the entire diameter and length of the expansion. A ram nose can be tapered to allow a growth or movement of materials into areas that would otherwise tare from the thinning of the expansion though segmented tool use.

For instance, a ram form pulling material from the outer edge of a bend will hold shape and the center line of the expansion without tarring or moving the center of the expansion. A segmented set of tools will draw material from the weakest area-being the outside of the bend. This moves the material and the center point of the size off-set and typically tares the material to a breaking point along the outside of the bend at the end of the straight.

Some of the benefits of a single strike machine include:

- Lower cost

- Faster cycle times

- Lower tooling costs

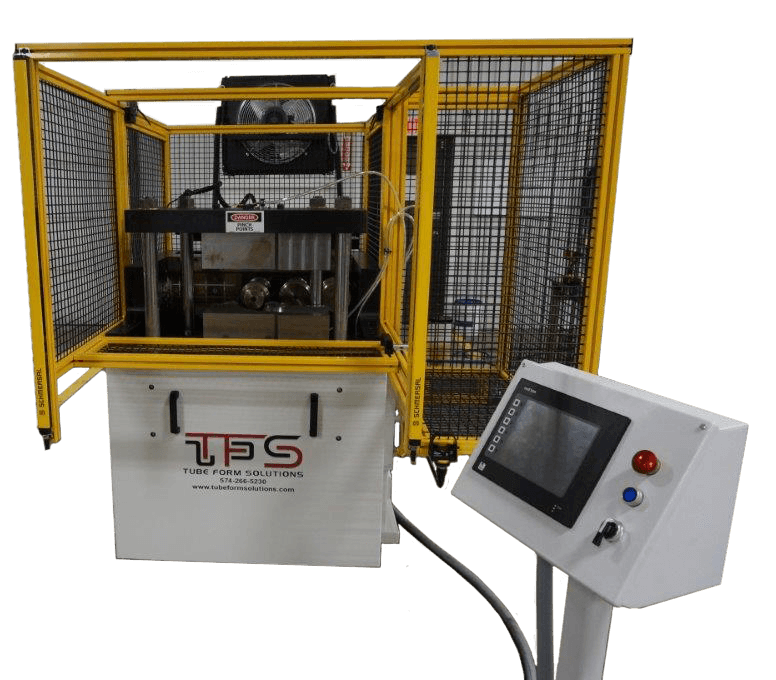

Despite these benefits, a single hit ram forming machine, like the TF-80, can only strike the material once. So this means that shapes that require a progression can't be accommodated on this type of machine.

Multi Strike Three Hit Expansion

Multi Strike Three Hit Expansion

Multi strike three hit expansion machines work to change the shape of a tube or pipe in a different way than single strike machines. On a multi strike end forming machine, diametric expansions of a tube near or inside of a bend are stretching work hardened material. Because the fingers work to expand on points until the desired diameter is met, the stretching that occurs is between the fingers and not in a complete circumference.

The benefits of this type of expansion include:

- Greater degree of expansion or reduction

- Greater flexibility because there are more parts on one machine

- Can handle complex shapes

A multi strike three hit expansions isn't always the best option, however. Not all applications warrant the greater purchase price or can benefit from the expanded capabilities. In fact, multi strike three hit expansion capable machines require longer, more in-depth set up and have longer cycle times. They also have greater tooling costs.

However, for applications where the specifications call for greater expansion/reduction, complex shapes, or flexibility then a multi strike machine like the 150 Multi Strike Ram Tube End Former really is the best option.

Learn More

Contact us to learn more about our full line of tube end former tooling and end forming machines, or let us help you find the right automated solution for your application!