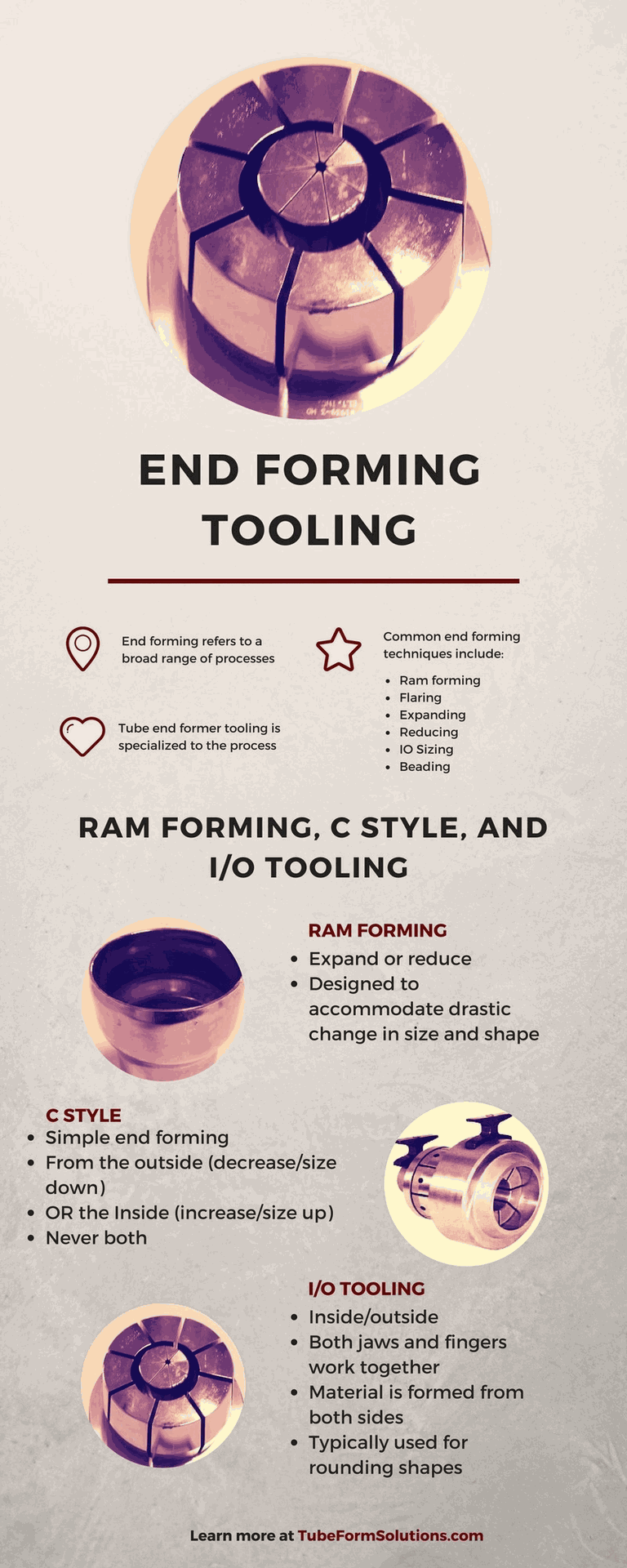

Each type of end forming tooling serves a specific purpose and is used for specific end forming processes. We've broken down three of the most common end forming tooling types below to illustrate how different each tooling type is. Keep an eye out for more end forming tooling breakdowns coming soon!

End Forming Tooling

Contact us to learn more about our full line of tube end former tooling and end forming machines, or let us help you find the right automated solution for your application!