CNC tubing benders offer users repeatability to perform even complex bends. With the technology that goes into a CNC tube bending machine doing the heavy lifting of bending, it is not surprising that CNC benders are often the bending machine of choice for applications as diverse as ship building and delicate aerospace applications. This wide range of applications, however, means that CNC benders come in a wide range of models and with a lot of options to consider. So, when looking for a CNC tubing bender, there are 4 basic criteria that can help narrow down the search.

Automation

Automation

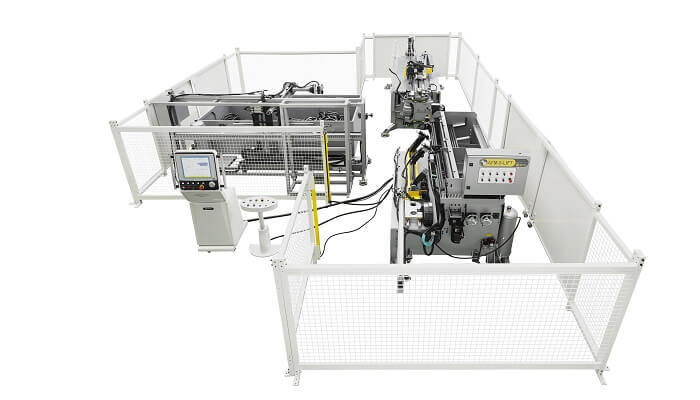

When searching for the right CNC tubing bender one of the easiest criteria to begin with is automation. For some applications, a fully automatic solution is a must. When this is the case, it immediately narrows the search.

Fully and semi-automatic bending machines are plentiful and can offer users a huge degree of flexibility, hence their popularity. We offer a number of bending machines, for instance, that are automatic. The 2B Series, for instance, is a fully automatic solution with a focus on cost effective performance. This CNC series features a hydraulic press die booster and a standard wiper die holder. A fully automatic solution, the 2B Series is versatile enough to satisfy most fully automated bending needs.

Power

For some applications, shear power becomes the most important selection criteria. When the tubing that needs to be bend is meant for heavy industry, you need to be sure the CNC tubing bender that is selected can perform.

For instance, heavy industrial tubes and pipes like those used in ship building, trucking, and other heavy applications can present challenges if the bender that is used is under powered. Often, when bending heavy tubes and pipes, it is necessary to choose a bender specifically designed and engineered to handle the additional power requirements.

Precision

Again, like heavy applications, high precision bending can sometimes require specifically designed machines. The A Series, for instance, is a high precision bending machine that we carry. It is one of the highest performance solutions on the market, with 3-4 electric CNC axes, multiple bending stacks, and unique DGT technology for the ultimate in precision and power.

Complexity

The complexity of the bends you will be performing is the last selection criteria. Very often complexity goes hand in hand with precision because complex bends tend to also require a great deal of precision.

When dealing with complex shapes like head rests, fuel lines, and heating/cooling systems often it is most effective to be able to perform both right and left bending in the same cycle. The ability to handle these types of complex shapes can dictate which benders are best suited. Our line of right and left-hand CNC benders, for instance, makes use of both right and left bending technology for maximum flexibility and minimal interference.

Learn More

Contact us at any time with any questions or comments you may have or to learn more about the CNC Tube Bender line. Click here or follow the link below to download a free introduction to tube bending.