We've talked before about the range of processes that fall under the heading "end forming" and we've begun to explore the various types of end forming available. Now we're going to turn our attention to two new types of end forming tooling; inline flare ram forming tooling and ram multi-strike tooling.

Inline Flare Ram Forming

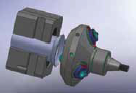

Ram Multi-Strike

Ram Multi-Strike

This type of tooling can be used for flaring, beading, large expansions, and reductions. The big advantage of using ram multi-strike tooling is that it allows all of the forming to occur in the same machine. This is because the tooling indexes automatically provide a robust and repeatable process in one machine instead of several.

Ram multi-strike tooling gradually moves the material being formed. This gradual movement helps to prevent stresses that could crack or break the material.

Learn More

Contact us to learn more about our full line of tube end former tooling and end forming machines, or let us help you find the right automated solution for your application!